QUEST 1

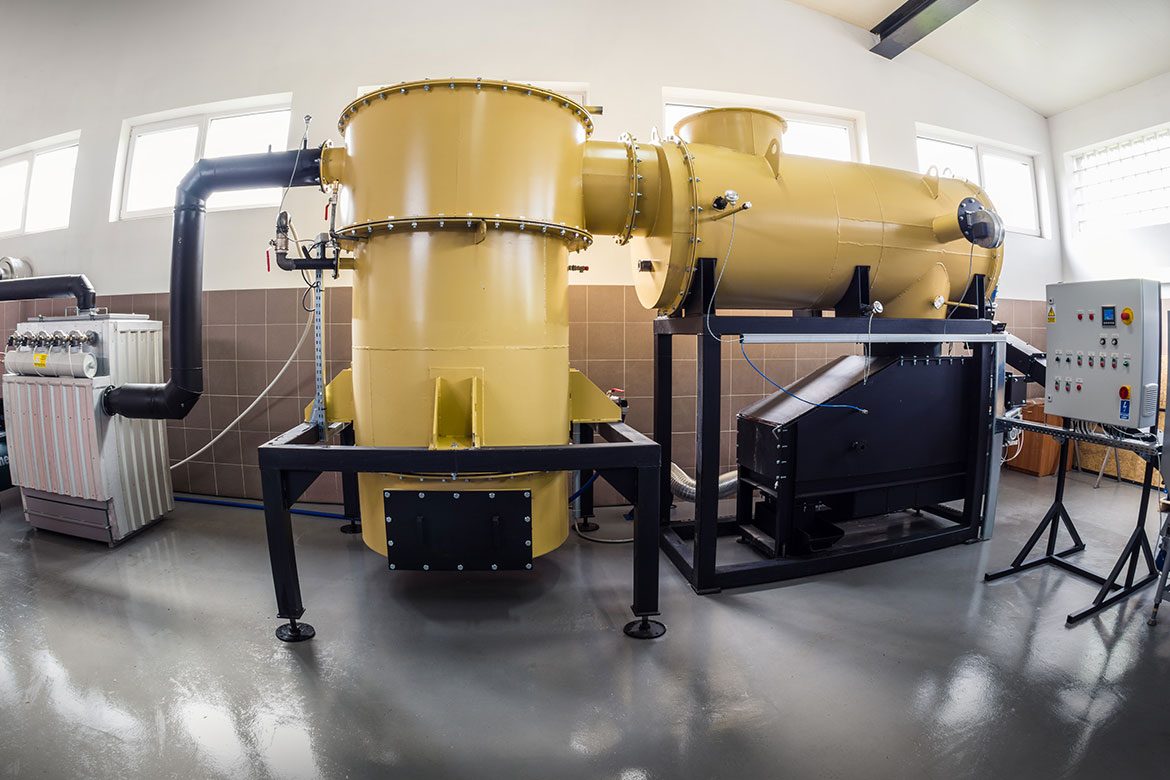

We offer a thermal sewage sludge disposal installation with energy recovery – QUEST 1, Qenergy’s own technology developed by our team of engineers.

The aim of the project is to meet the growing demand for sewage sludge treatment. Thanks to the thermal processing, the sludge is neutralized at the maximum relieving of the natural environment.

The installation consists of a fuel feeder, control cabinet, furnace with moving grate, post-combustion chamber, steam boiler and bag filter.

The design parameters of the QUEST 1 installation are as follows:

| Installation efficiency | 50 – 500 kg/h |

| Thermal power of the installation between | 100 kW – 1MW |

| The degree of drying of the sludge up to | 80 % s.m. |

| The amount of non-flammable parts equal approx. | 30-50% |

| The calorific value in the dry and ashless state of | 21 MJ/kg |

| The opal value in operating condition | 10 MJ/kg |

From left: exhaust fan, compressor, bag filter with automatic bag cleaning system photo: Mateusz Andrzej Olender.

We offer delivery of the complete product that provides the management of sewage sludge, while guaranteeing:

- sanitary safety

- reducing the volume of waste

- limiting the negative impact on the environment

The system meets the emission standards in accordance with the Regulation of the Minister of the Environment dated 4 November 2014 on emission standards for certain types of installations, fuel combustion sources and incineration or co-incineration devices for waste.

A furnace with a movable grate photo: Mateusz Andrzej Olender

In addition, QUEST 1 also functions as a device that enables the production of process steam or the production of process heat. This is very important from the point of view of a savings economy – it provides an independent and relatively cheap source of energy from recovery.

Analysis of thermally processed sludge shows:

- Roasting loss at 1.8%

- Carbon content in the slag: 1.5%

- Phosphorus content in slag: 11.6%

Processed sewage sludge

The process of technological disposal of sewage sludge is carried out in conditions allowing effective use of the heat of the combusted substance.

The parameters characterizing the operation of the device have a positive effect on the quality of the resulting gases, which during the inspection show the correct emission values.

We encourage you to contact us for consultation, during which we will try to suggest an installation best suited to your expectations.

by our clients and partners,

as evidenced by numerous references.