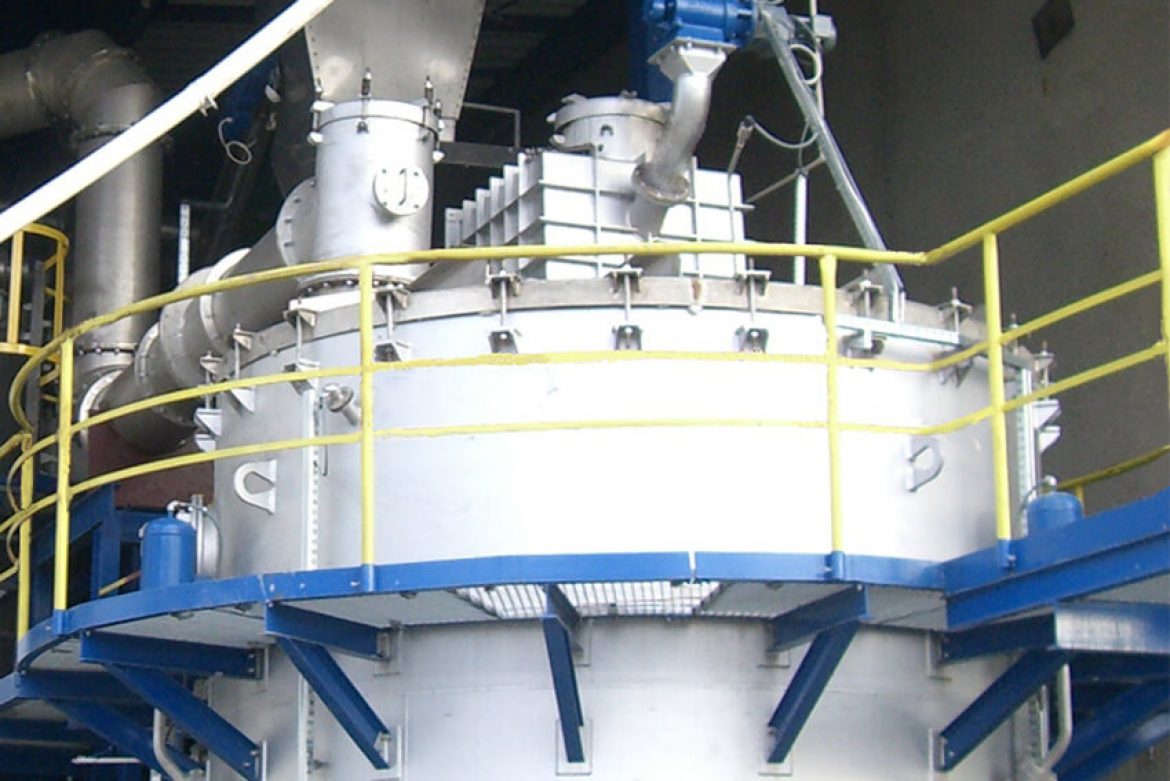

We offer a new version of our gasifier – Gasifier QM12

Gasification is a process that converts carbonaceous materials, such as biomass, wood, various types of waste including municipal and industrial waste, coal, petroleum, petroleum coke, into a calorific gas consisting mainly of carbon monoxide, hydrogen and methane under high temperatures.

The process is based on a chain of reactions between the carbon in the fuel and the supplied oxidizer: oxygen (from the air), steam, hydrogen or carbon dioxide. The gasification process takes place in the temperatures between 400 and 850 °C. The final product of the process is combustible gas. The gas is called producer gas or syngas (or wood gas when fuelled by wood) and may be more efficiently converted into energy (both thermal and electric) than would be possible by direct combustion of the fuel. Also, corrosive ash elements such as chloride and potassium may by refined out by the gasification process, allowing high temperature combustion of the gas from otherwise problematic fuels.

Our gasification systems separate the gasifying process from combustion of the produced gas by using a separate gasifying and combustion chamber. Therefore, the whole process is divided into two major elements:

- Devolatilization of the organic substances under high temperature, often above 1000 °C and then transformation of remaining organic carbon at app. 800 °C into a mixture of carbon monoxide, carbon dioxide and hydrogen. This takes place in the presence of air and steam.

- Combustion of this gas in a separate combustion chamber under fully controlled conditions with the possibility of multilevel gas and flue gas treatment.

Separating the gasification and combustion process allows for much better control of the whole process, which in turn enables technological changes to improve and fine-tune the whole system.

Our knowledge and experience are appreciated

by our clients and partners,

as evidenced by numerous references.

by our clients and partners,

as evidenced by numerous references.